Fish Merchant

A UK fish merchant was hiring 8 skips per week to remove mixed waste including polystyrene to landfill at a cost of £170 per skip. Total cost per week was £1,360 or £16,320 per year!

A Styromelt™ system was installed at the merchants to densify the polystyrene waste instead of sending it to landfill. The cost savings turned out to be very significant.

By seperating the polystyrene the merchant needed only one skip per week for the rest of the mixed waste.

The remaining polystyrene was densified using the Styromelt™ with a running cost of approx 48p per hour or £76 per month to produce around 1 ton of completely sterile, easily stored product each month.

The merchant then sold this product for £100 to a recycler so they actually made a small profit on the running costs of the Styromelt™ machine!

The merchant now saves approx £1,190 per month or £14,280 a year thanks to Styromelt™ and the machine has more than paid for itself in a short period of time.

French Merchant

A merchant in France was spending €2,000 per month or €24,000 a year for the local council to collect tubs of polystyrene waste from their premises.

This cost to the company has been removed by installing a Styromelt™ system to densify and sterilise their waste polystyrene. They now plan to sell the densified product to a local recycling company.

Packaging Company

A packaging company in the UK was producing 8 tonnes of waste cardboard which it intended to sell to a local recycling company. The recycling company refused the waste because it had polystyrene trays mixed in with it.

The packaging company installed a Styromelt™ system and sorted their waste into two types. The cardboard was sold to the recyclers and the polystyrene was densified in order to be sold as well.

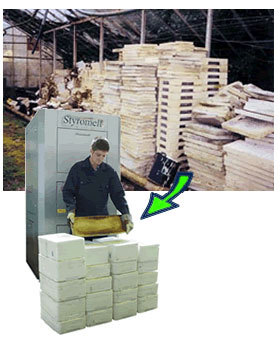

Agricultural Waste

A huge pile of used horticultural EPS packaging that was contaminated with soil, ivy and slugs and had been left untouched for at least ten years gave us the opportunity to test the Styromelt™ with some very challenging material. The thermal densifier does not crush or shred the material; it uses a thermal process so contaminates like food or soil do not damage the machine.

It can be used for EPS, EPP and any other plastics to reduce the volume of a waste material so it can be economically transported to a recycler or

to landfill if neccesary.

|