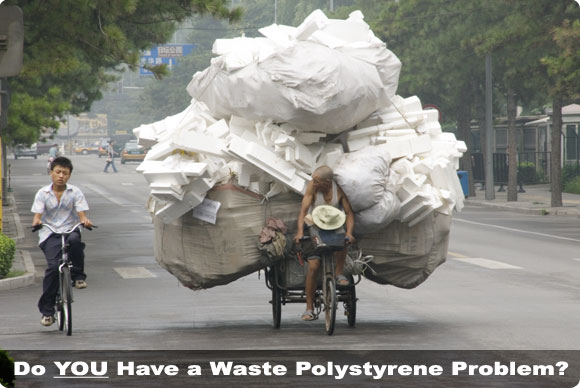

Polystyrene (styrofoam) - The Problem

Polystyrene (styrofoam) is an excellent packaging material due

to its insulating and protective properties. Unfortunately, once

goods are delivered

and opened polystyrene then becomes a waste material that companies

must pay to dispose of. Large, bulky pieces of polystyrene can

take up significant space in a waste skip which means the skip

becomes full more quickly and therefore needs to be emptied more

often – therefore more cost.

It is conservatively estimated that hundreds of thousands of

tons of waste polystyrene is produced and sent to landfill

on an annual basis in the UK alone. This material is very

lightweight

compared to its volume so it is not hard to imagine how much

precious landfill space is filled with tons and tons

of polystyrene.

Disposing of Polystyrene has the following drawbacks:

- Boxes and packaging can take up large volumes of storage

space prior to removal.

- Fish/Meat packaging is contaminated with blood, fluids etc

and so can be a health hazard and attract vermin when in storage

prior to removal.

- Skip hire or running costs of disposal lorries are very high.

- Because boxes and packaging take up a lot of space transport lorries or skips are filled very quickly.

- High landfill charges make disposal expensive and bad for the environment

|

The Styromelt™ drastically reduces the volume of waste polystyrene

by thermal densification.

|

Styromelt™ - The Solution

The Styromelt machine from Styromelt Ltd essentially melts polystyrene

(styrofoam) to form a dense block of material that is reduced

in volume by

over

95%

of the

original material. So a 2 cubic metre load of polystyrene comes

out of the machine as a small block approximately 90cm x 25cm

x 5cm. The block can be stored then sold to recycling companies

who then turn it into fuels such as diesel or new products

such as garden furniture.

The densified blocks are sterile,

easy to handle and can be stored indefinately. This means that

several loads can be put through the machine over time until

sufficient quantities have been produced for either sale or disposal.

There is an emerging market for blocks for incineration,

recycling and for the production of fuels. Recyclate value

of blocks

is based on oil price and is currently £80- £170

per tonne based on volume.

Further benefits are:

- Processed blocks are recyclable as product or fuel and can

actually be sold to recyclers.

- Greater compaction rate - up to 10 times greater than hydraulic

compaction.

- In-situ sterilisation of plastic material means the product can be stored indefinately.

- Ability to deal with contaminants such as blood, organic

matter, metal, stone and glass without damage or failure.

- Thermal compaction is a batch process and incurs no energy costs until the machine is full. The machine could be described as an ‘electric skip’.

- Process is virtually silent running.

- Machinery can be operated with very few skills.

- Machinery occupies a small footprint, ideally suited for

retrofitting in supermarket or municipal areas.

- The machine

is weather proofed for outside use and is IP56 rated.

|

• Local Authorities

• Fisheries Industry

• Cruise / Ferry Industry

• Smoke Houses

• Manufacturers

• Hospitals

• Arenas

• Electronics Companies

• Waste Management

|

|